Acrylic Denture

Acrylic Denture. Mobile Number 01797522136, 01987073965. Acrylic dentures are a cost-effective, removable solution for replacing missing teeth, consisting of a pink acrylic base to mimic gum tissue and acrylic or ceramic teeth. They can be full or partial, with partial dentures using metal clasps to attach to remaining teeth. While affordable and effective for restoring function and appearance, acrylic dentures are generally less durable, can be bulkier, and may require replacement every 5-8 years due to wear and gum resorption.

Components and Materials of Acrylic Denture

- Base: Made from a hard acrylic resin, the base is shaped to resemble your natural gum tissue.

- Teeth: Artificial teeth are made from specialized plastic (composite resin) or ceramic, chosen for their lightweight, easy-to-shape, and non-toxic properties.

- Clasps: For partial dentures, metal or clear clasps are used to anchor the denture to remaining natural teeth, providing stability.

Types of Acrylic Dentures

- Complete Dentures: Used when all teeth are missing, these rely on suction or the acrylic base to stay in place.

- Partial Dentures: These replace one or more missing teeth and are held in place by clasps that secure them to the surrounding natural teeth.

Advantages of Acrylic Denture

- Affordable: Acrylic dentures are one of the most cost-effective tooth replacement options.

- Customizable: They are custom-made for a personalized fit, restoring function and facial structure.

- Temporary Solution: They can serve as a temporary option after tooth extractions, allowing gums to heal before a permanent solution is placed.

- Repairable: Acrylic dentures can often be repaired and adjusted by a dentist or denturist.

Disadvantages of Acrylic Denture

- Durability: They are less durable than some other options and may need replacement every 5-8 years due to wear and gum changes.

- Appearance: Metal clasps on partials can sometimes be visible, affecting aesthetics.

- Comfort: They can be bulkier and may impair taste and comfort compared to fixed restorations.

Care and Maintenance of Acrylic Denture

- Cleaning: Proper cleaning is essential to prevent staining and maintain hygiene.

- Regular Check-ups: Dentists should monitor the fit and condition of the dentures and make adjustments as needed.

Location of Acrylic Denture

HRTD Dental Services and Technology, Abdul Ali Madbor Mansion, Section-6, Block-Kha, Road-1, Plot-11, Metro Rail Piller Number 249, Mirpur-10 Golchattar, Dhaka, Bangladesh. Mobile Phone Number 01797522136, 01987073965.

Acrylic Complete Denture

An “acrylic complete denture” is a type of removable dental prosthesis made from polymethyl methacrylate (PMMA) (acrylic) that replaces all missing teeth and supporting soft tissues in one arch of the mouth, allowing for chewing, speaking, and improved facial structure. Acrylic is a lightweight, cost-effective, and easily moldable material that can be modified or repaired, making it a popular and affordable choice for full dentures.

Key Characteristics:

- Material: Made from PMMA, a type of plastic that is strong and durable.

- Function: Replaces all natural teeth in the upper or lower jaw.

- Appearance: The pink acrylic base mimics natural gum tissue, and the teeth can be made to look natural.

- Support: The denture rests on the soft tissues of the mouth for support.

Benefits of Acrylic Complete Dentures:

- Cost-Effective:Acrylic is generally less expensive than other materials, making it a budget-friendly option.

- Ease of Adjustment:The acrylic material is easy to repair and adjust, which can be beneficial if modifications are needed.

- Improved Function:They help with chewing, speaking, and maintain the structure of the mouth by preventing sagging.

- Comfort:The lightweight nature of the acrylic provides a comfortable fit.

Considerations:

- Aesthetics: While functional, acrylic can sometimes appear less realistic and reflect light differently than natural teeth or porcelain.

- Wear: Acrylic can wear down over time, though the material is durable.

Advantage of Acrylic Partial Denture

Acrylic partial dentures are an affordable, aesthetically pleasing option for replacing missing teeth, offering natural-looking results and easy adjustments and repairs. Their lightweight and flexible nature provides comfort, and their quick fabrication makes them ideal for immediate tooth replacement or as a temporary solution while awaiting other procedures.

Key Advantages

- Affordability:Acrylic partial dentures are a cost-effective option, making them accessible for patients on a tighter budget or those seeking a temporary solution.

- Aesthetic Appeal:The acrylic material can be designed to match the natural color of your gums and teeth, providing a seamless and natural-looking restoration.

- Ease of Repair and Adjustment:The flexible nature of acrylic allows for simple modifications, such as adding more teeth or relining, without the need for complete replacement.

- Lightweight:Acrylic is a lightweight material, which can lead to a more comfortable wearing experience and less pressure on the supporting tissues.

- Quick Fabrication:Acrylic dentures can be created relatively quickly, making them a good choice for urgent tooth replacement needs or as immediate dentures after extractions.

- Improved Functionality:By filling the gaps left by missing teeth, these dentures help to restore your ability to chew effectively and improve your clarity of speech.

- Temporary Solution:Their affordability and ease of adjustment make acrylic partials an excellent temporary option for patients waiting for more permanent solutions like implants or metal dentures.

Advantage of Acrylic Complete Denture

Acrylic dentures offer advantages in affordability, quick fabrication for prompt tooth replacement, and lightweight comfort. They are also easily adjustable, repairable, and customizable to match natural colors, and are a versatile option for both full and partial tooth loss.

Cost-Effectiveness & Quick Fabrication

- Affordable:Acrylic is a budget-friendly material compared to metal or implant-supported options, making it accessible for more people.

- Fast Manufacturing:Dentures can be made quickly, which is ideal for patients needing a fast or temporary solution.

Comfort & Adaptability

- Lightweight:The material’s lightness provides comfort, especially for first-time denture wearers.

- Easy Adjustments:Acrylic dentures can be relined, adjusted, and repaired easily if your mouth changes or if a tooth breaks.

- Good for Immediate Dentures:They are a great option for “immediate dentures,” which are placed the same day teeth are removed.

Aesthetics & Versatility

- Natural Appearance:Acrylic’s ability to mimic the opacity and color of natural gums and enamel creates a lifelike and appealing smile.

- Versatile:Acrylic can be used for both partial (replacing some teeth) and complete (replacing all teeth) dentures.

Other Benefits

- Hypoallergenic: The material is a good alternative for people with sensitivities to other denture materials.

- Easy Maintenance: They are easy to clean and maintain.

Materials Used for Acrylic Denture

Acrylic dentures use a heat-cured acrylic resin for the pink, gum-colored base and can use other materials like porcelain or composite resin for the white teeth. The pink resin is a polymer known as Poly(methyl methacrylate) (PMMA), mixed with a liquid methyl methacrylate (MMA) monomer, while the teeth contain pigments for color and can be made from acrylic, porcelain, or composite resin.

Materials for the Denture Base

- Acrylic Resin (PMMA): This is the most common material, a plastic that mimics the look and feel of natural gums.

- Components: It consists of a powder (PMMA polymer) and a liquid (MMA monomer), along with additives like hydroquinone and benzole peroxide to control polymerization.

- Properties: Lightweight, affordable, and can be tinted to match natural gum color.

Materials for the Denture Teeth

- Acrylic Resin:Similar to the base material, these are a common and cost-effective choice for teeth.

- Porcelain:These teeth are more durable, have a natural translucency, and are often used for cosmetic purposes.

- Composite Resin:Another option for teeth, this material is often used with other types of dentures.

Other Related Materials

- Metal Alloys: While not used in full acrylic dentures, materials like cobalt-chromium may be used for the framework in some partial dentures.

- Flexible Thermoplastics (Nylon): These are used for flexible partial dentures, offering a more comfortable and aesthetically pleasing alternative to traditional acrylics.

Why People Choose Acrylic Denture?

People choose acrylic dentures mainly because they are a cost-effective and customizable option for replacing missing teeth, offering a natural appearance and easier adjustments than metal alternatives. They are a lightweight, comfortable choice for both complete and partial dentures and are relatively quick to create.

Cost-Effective

- Affordability: Acrylic dentures are a budget-friendly option compared to other types of dentures, such as those with metal frameworks, making them accessible to more people.

Customization and Appearance

- Natural Look:Acrylic dentures can be tailored to match the color, shape, and size of your natural teeth and gums, providing a natural and seamless appearance.

- Aesthetic Adjustments:The material is moldable, allowing for easier adjustments and modifications by a dental technician to improve comfort and aesthetics.

Convenience and Repair

- Easy Adjustment and Repair:Acrylic dentures can be easily adjusted, relined, and repaired by a dentist if they break, wear down, or need modification.

- Quick Creation:They are a relatively quick option to create, making them suitable for a temporary solution while waiting for more permanent options like implants.

Comfort and Function

- Lightweight:The acrylic material is lightweight, contributing to the comfort of the denture.

- Stability:They provide a rigid structure, offering stability for chewing and speaking.

- No Metal Clasp Option:For those who dislike metal, acrylic partial dentures can use non-metal clasps for a better aesthetic.

Why Acrylic Dentures are Better Than Flexible Dentures?

Acrylic dentures are often better than flexible dentures for patients needing a more durable, stable, and cost-effective solution, as they are generally easier to repair, have a longer lifespan, and are less expensive upfront. However, the choice depends on individual needs, as flexible dentures offer superior comfort for sensitive gums and a more natural look with less visible clasps.

Advantages of Acrylic Dentures

- Durability and Longevity:Acrylic dentures are designed to be more durable and can last longer than flexible dentures, often up to 10 years compared to about 8 years for flexible ones.

- Cost-Effective:They are a more affordable option, making them a good choice for budget-conscious individuals.

- Easier to Repair:Unlike flexible dentures, which are difficult to repair and may require replacement, acrylic dentures can often be adjusted or repaired by a dentist.

- Stable Fit:Acrylic provides a rigid base, which can offer a secure and stable fit in the mouth.

- Secure Bond:The acrylic material adheres well to the base, ensuring the teeth bond securely to the denture.

When Flexible Dentures Might Be Preferred

- Enhanced Comfort:Flexible dentures are made from a soft, thin, and lightweight material that adapts to the natural contours of the mouth, offering superior comfort and an improved fit.

- Improved Aesthetics:The clear nature of the flexible material allows the natural gum color to show through, making the denture less noticeable and more natural-looking than colored acrylic options.

- Good for Sensitive Gums:Their adaptive, hypoallergenic nature makes them an excellent choice for people with sensitive gums or a history of allergic reactions to acrylic.

- Better for Some Situations:For patients who want to avoid metal clasps, flexible dentures can provide a metal-free, aesthetically pleasing alternative with hidden, tissue-colored clasps.

Key Considerations

- Cost:Flexible dentures are generally more expensive due to their advanced materials and comfort features.

- Repairability:Acrylic dentures are easier to repair, while flexible ones often need replacement if damaged.

- Maintenance:Flexible dentures require special, approved cleaning solutions to prevent damage and discolouration, whereas acrylic dentures can be cleaned with standard, cost-effective products.

Durability of Acrylic Denture

Acrylic dentures typically last between 5 and 10 years, with an average lifespan of about 5 years, though this can vary based on factors like proper care, material quality, and the specific type of acrylic. Acrylic dentures are prone to fractures due to their inherent mechanical limitations but are known for being easy to repair and reline. To maximize their durability, regular maintenance, adherence to dental care instructions, and professional adjustments are crucial.

Factors influencing acrylic denture durability

- Material Quality:The specific type of heat-cured acrylic resin used can affect the denture’s overall strength and lifespan.

- Care and Maintenance:Regular cleaning, proper storage, and avoiding abrasive materials help extend the life of your dentures.

- Oral Health:Changes in the gum and bone structure (alveolar ridge) over time necessitate relining or replacement of the denture to maintain a proper fit.

- Repair:Dentsure bases made of acrylic are susceptible to fracture, but they can be repaired, often with the addition of reinforcing fibers to increase strength.

How to extend acrylic denture life

- Regular Dental Check-ups: Visit your dentist every 3-6 months for routine maintenance and to monitor any changes in your mouth that may require adjustments.

- Professional Cleaning: Have your dentures professionally cleaned and adjusted by your dentist.

- Proper Handling: Handle your dentures carefully to avoid damage or fracture.

- Follow Dentist’s Instructions: Adhere to your dentist’s specific instructions for care and maintenance to ensure the best possible outcome.

Processing of Acrylic Denture

Acrylic denture processing is a multi-step laboratory procedure that begins with flasking, or creating a mold around the wax denture, then removing the wax to create a cavity. Next, acrylic resin dough is packed into the mold, and the flask is cured by heating it in a water bath to polymerize the acrylic. Finally, the denture is de-flasked by removing the mold, and the finished denture is then trimmed, finished, and polished before being returned to the patient.

1. Flasking

- The wax denture, which consists of the wax base and the teeth, is embedded in dental stone inside a two-part metal flask.

- This creates a mold, or a cavity, that will later be filled with acrylic resin.

2. Wax Elimination

- After the flask is filled with the dental stone and the wax pattern, the flask is placed in a boiling-out machine.

- The boiling water eliminates the wax, leaving a clean cavity in the mold.

- A separator, such as a layer of soapy water or Vaseline, is then applied to the plaster surfaces to prevent the acrylic from sticking to the mold.

3. Mixing and Packing Acrylic Resin

- A heat-cured acrylic resin, made from a liquid monomer and a powder polymer, is mixed to form a dough.

- This acrylic dough is then packed into the prepared mold cavity within the flask.

- The flask is then closed and compressed to ensure the acrylic fills the entire mold.

4. Curing

- The flask is heated in a water bath to a specific temperature for a set amount of time.

- This process, known as heat curing, causes the liquid monomer and powder polymer to chemically react, polymerizing the acrylic resin into a hard, permanent material.

5. Deflasking and Finishing

- Once the curing process is complete, the flask and the denture are cooled slowly to room temperature.

- The flask is then opened, and the stone mold is carefully separated from the flask.

- The finished acrylic denture is then removed from the stone mold, trimmed of any excess material, and polished.

Processing of Acrylic Complete Denture

Processing a complete acrylic denture involves flasking the waxed denture model and cast in dental stone, wax elimination to remove the wax, packing and curing heat-activated acrylic resin into the mold, de-flasking to remove the denture, and finally finishing and polishing the completed denture. This process creates a durable acrylic denture that replaces the wax and the initial acrylic base.

Step-by-Step Acrylic Denture Processing

- 1. Flasking (Investing):

- The dental cast with the waxed denture is placed into a two-piece metal container called a flask.

- Dental stone or plaster is poured to enclose the cast and denture, creating a mold for the resin.

- 2. Wax Elimination (Dewaxing):

- The flask is placed in boiling water to melt and wash away the wax pattern, leaving a void in the stone mold that replicates the denture’s shape.

- 3. Packing Acrylic Resin:

- The acrylic resin is mixed to a dough-like consistency.

- The mold cavity is packed with the acrylic dough.

- The flask is closed, and the resin is compressed to fill the mold and eliminate air bubbles.

- 4. Curing:

- The flask is placed in a heat source, usually a water bath, to polymerize the acrylic resin.

- Different curing cycles are used, including slow curing in a water bath or a shorter, more rapid curing process with boiling.

- 5. De-flasking (Divesting):

- After the acrylic has cured and the flask has cooled slowly to room temperature, the mold is carefully separated from the flask.

- The cured denture is then carefully removed from the stone or plaster mold.

- 6. Finishing and Polishing:

- The rough edges of the denture are trimmed.

- The denture is then finished and polished to create a smooth, comfortable, and aesthetically pleasing surface.

Processing of Acrylic Partial Denture

Processing of an acrylic partial denture involves flasking a wax pattern on a dental cast, dewaxing to create space, adding separating media, packing the acrylic resin dough, and then curing the acrylic to harden it. The final stages include deflasking to remove the denture from the cast, followed by finishing and polishing to ensure a comfortable, natural-looking fit for the patient.

Step-by-step breakdown of the processing

- 1. Flasking:The wax denture (which includes the teeth and clasps) is placed in a flask, and a dental cast is poured around it.

- 2. Dewaxing:The flask is heated in boiling water or an electric oven to melt and remove the wax, leaving the denture pattern and the cast exposed.

- 3. Separating Media:A separating solution is applied to the cast and flask to prevent the new acrylic from sticking to the surfaces.

- 4. Packing the Acrylic Resin:Acrylic resin dough is placed into the mold created by the dewaxed wax pattern.

- 5. Curing:The flask is closed and subjected to pressure and heat, often in a water bath or electric oven, to polymerize the acrylic and cure it into a hard denture.

- 6. Deflasking:After curing, the finished denture is removed from the flask and the cast.

- 7. Finishing and Polishing:Any excess acrylic (flash) is removed, and the denture is smoothed and polished to create a comfortable fit and a natural appearance.

Key considerations during processing

- Clasps:Wrought wire clasps may be added before or after the main acrylic processing, depending on the design.

- Undercuts:The initial wax pattern is designed to account for undercuts on the cast, which are necessary for the denture’s retention.

- Quality:The overall process ensures the denture precisely fits the patient’s mouth by replicating the unique features of their jawbone, teeth, and gums.

Technology for Acrylic Denture

Modern technology for acrylic dentures involves a digital workflow using CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) and 3D printing, which offer superior fit and faster production compared to traditional methods. Digital impressions replace manual molds, and design software creates custom dentures. 3D printers then fabricate the denture base using biocompatible acrylic resins, with the final teeth often integrated or bonded.

The Digital Workflow

- 1. Digital Impressions:Instead of traditional plaster molds, intraoral scanners capture precise digital images of a patient’s mouth.

- 2. CAD Software:Dental technicians use specialized software to design the denture based on these digital impressions, allowing for accurate anatomical fit and custom tooth arrangement.

- 3. 3D Printing (Additive Manufacturing):The digital design is sent to a 3D printer, which builds the denture layer by layer using high-performance biocompatible acrylic resins.

- 4. Milling (Subtractive Manufacturing):Alternatively, the final denture can be milled from a pre-cured block of acrylic, which results in a highly precise and strong final product.

Benefits of Digital Technology

- Improved Accuracy and Fit:Digital scanning and design lead to a more precise fit, reducing the likelihood of sore spots and requiring fewer adjustments.

- Faster Production:The digital process significantly reduces the time needed to fabricate dentures, allowing for faster turnaround.

- Customization:Dentures can be highly customized to mimic the natural appearance and structure of teeth, improving aesthetics.

- Durability:Modern acrylic resins and manufacturing processes result in stronger, more durable dentures compared to traditional versions.

- Predictable Results:Digital workflows provide more predictable and consistent outcomes, ensuring a better final product for the patient.

- Digital Storage:Digital files are stored, making it easy and quick to create replacement dentures if the originals are lost or broken.

Technology for Acrylic Complete Denture

Technology for acrylic complete dentures includes traditional techniques, involving manual carving and molding of wax with acrylic teeth, and CAD/CAM technology, which uses digital scanning, 3D design, and milling or 3D printing to create more accurate, efficient, and customized dentures with improved fit and potentially reduced chair time. Digital methods may also incorporate advanced materials and even embedded sensors for “smart” prosthetics.

Traditional Acrylic Denture Technology

- Impression & Model:The process begins with a dental impression taken from the patient’s mouth, which is then used to create a stone (gypsum) model.

- Wax Setup:An experienced lab technician sets artificial teeth into wax rims on the model to simulate the natural arrangement for aesthetics and function.

- Flask and Investment:The wax setup is invested in a two-part flask with plaster, which is then boiled to melt the wax, leaving an empty mold.

- Packing & Curing:Acrylic powder and liquid are mixed, packed into the mold, and cured under heat and pressure in a water bath, which hardens the acrylic and embeds the teeth.

- Finishing:The cured denture is removed, inspected, and then polished for final delivery to the patient.

Digital/CAD/CAM Technology

- Digital Scanning:Instead of physical impressions, a digital scanner creates a 3D image of the patient’s mouth or a stone model.

- 3D Design:The digital data is used in a computer-aided design (CAD) program to create a virtual 3D model of the denture.

- Manufacturing:The digital model is then sent to a computer-aided manufacturing (CAM) machine to be either:

- Milled: A solid block of material is precisely machined to form the denture.

- 3D Printed: The denture is built layer by layer using a 3D printer (additive manufacturing).

- Benefits:

- Improved Accuracy: Digital methods offer greater precision and fit compared to conventional techniques.

- Efficiency: Reduces the number of appointments and lab procedures needed.

- Patient Involvement: Patients can participate more directly in the aesthetic design process virtually.

- Biocompatibility: Improved material properties, such as reduced porosity.

- Smart Features: Emerging technologies allow for the integration of sensors to monitor oral conditions.

Technology for Acrylic Partial Denture

Modern technologies for acrylic partial dentures include digital impressions, computer-aided design (CAD), and computer-aided manufacturing (CAM) with 3D printing or milling. These digital workflows replace traditional physical molds with intraoral scanners, allowing for highly precise, individualized designs. 3D printing offers rapid prototyping for trial dentures, while CAM milling from dense acrylic blocks creates strong, accurately fitting final prosthetics, improving durability, biocompatibility, and patient satisfaction.

Digital Workflow Steps

- 1. Digital Impression:Instead of traditional physical molds, an intraoral scanner creates a digital 3D model of the patient’s mouth.

- 2. CAD Design:Lab technicians use CAD software to design the partial denture, allowing for precise customization of size, shape, and color, and to address any undercuts in the mouth.

- 3. CAM Fabrication:

- 3D Printing: A trial or prototype denture can be printed layer by layer using a light source to set liquid resin, allowing the clinician and patient to approve the aesthetics and fit.

- Milling: The final denture can be milled from a dense, pre-polymerized acrylic block using cutting instruments to remove excess material, resulting in a durable and accurately fitting appliance.

Benefits of Digital Technology

- Precision and Accuracy:Digital scans and CAD/CAM processes lead to a more precise and individualized fit compared to traditional methods.

- Durability:Modern, single-unit acrylic materials are stronger and more durable, offering better resistance to wear and tear.

- Improved Biocompatibility:Milling produces a dense, smooth surface with less residual monomer, making the denture more biocompatible.

- Efficiency:The digital workflow can reduce the number of patient appointments needed for fabrication.

- Enhanced Aesthetics:Digital design allows for perfect color matching and shaping to create a highly natural-looking and realistic result.

Limitations of Conventional vs. Digital

- Traditional Methods: Relied on physical molds and manual processing, which could lead to inaccuracies and more frequent adjustments.

- Digital Workflow: By implementing digital surveys, CAD software can better account for mouth structure, reducing the need for extensive manual adjustments and improving overall fit and function.

Future Trends

- The development of more advanced biocompatible materials and implant-supported options are further expanding the capabilities of partial dentures.

Traditional and Digital Impression for Acrylic Full Denture

Both traditional and digital impressions are used to create acrylic full dentures, but they differ in technique and patient experience. Traditional impressions use trays and impression materials like alginate to capture a physical model, while digital impressions use intraoral scanners to create a 3D virtual model. Digital methods offer greater patient comfort, faster turnaround, and potentially improved accuracy and fit due to their precision, though they require an initial investment in technology and specialized training. Traditional methods, however, are a well-established and cost-effective option, with results comparable to digital methods in some studies for complete denture fabrication.

Traditional Impression Method

- Process:A dental professional places a tray filled with an impression material (like alginate or zinc oxide eugenol) into the patient’s mouth to capture the shape and contours of the oral tissues.

- Output:A physical, stone model is produced from the impression, which serves as the basis for creating the acrylic denture.

- Pros:A familiar and cost-effective process for many practices.

- Cons:Can be uncomfortable for patients due to the tray and impression materials.

Digital Impression Method

- Process:A dentist uses an intraoral scanner to directly capture 3D digital data of the patient’s mouth and then uses this virtual model to design and fabricate the denture.

- Output:A digital (STL) file that can be used to 3D print or mill a denture.

- Pros:

- Patient Comfort: Eliminates the need for messy materials and can be faster.

- Accuracy & Efficiency: Digital models offer high precision and can be quickly transmitted to a lab for fabrication.

- Consistency: Digital workflows can yield more consistent outcomes.

- Cons:

- Cost: Requires an initial investment in technology and training for dental professionals.

- Adoption: The adoption of digital methods for complete denture fabrication has been slower due to these factors.

Key Differences

- Materials vs. Scanners: Traditional uses physical materials; digital uses optical scanners.

- Tangible vs. Virtual Models: Traditional produces a physical model; digital generates a 3D virtual model.

- Workflow: Digital workflows are often faster and more streamlined once the technology is implemented.

Traditional and Digital Impression for Acrylic Partial Denture

For an acrylic partial denture, traditional impressions use physical trays with impression material, while digital impressions use intraoral scanners to capture 3D data of the oral structures. Digital methods offer enhanced patient comfort, accuracy, and faster digital transfer to the lab, but traditional methods remain effective and may be more economical in some situations. The choice depends on factors like cost, time efficiency, and patient preference.

Traditional Impression Method for Acrylic Denture (Partial)

- 1. Process:A tray filled with a soft, moldable material is placed in the mouth to capture a negative mold of the teeth and gums.

- 2. Output:The impression material hardens, creating a physical mold from which a dental cast is made.

- 3. Advantages:

- Cost-effective: May have lower initial costs and recurring expenses for material.

- Effectiveness: Proven to be an effective method for creating denture models.

- 4. Disadvantages:

- Patient Discomfort: Materials can be uncomfortable, gooey, or trigger a gag reflex.

- Messy: The process can be messy for the patient and practitioner.

- Physical Storage: Impressions and models require physical storage space in the practice.

- Increased Steps: More steps in the process increase the possibility of errors.

Digital Impression Method for Acrylic Denture (Partial)

- 1. Process:A dental professional uses an intraoral scanner to take direct, quick scans of the patient’s teeth and gums, creating a 3D digital model.

- 2. Output:The scanner captures 3D data, which is converted into digital files (like STL files) for use with CAD/CAM software.

- 3. Advantages:

- Patient Comfort: Non-invasive, quick, and painless, eliminating gagging.

- Accuracy: Captures detailed digital data for precise dental anatomy.

- Efficiency: Faster process and direct digital transfer to the lab.

- Storage: Digital files are stored electronically, saving space and improving access.

- 4. Disadvantages:

- Cost: May require an initial investment in expensive intraoral scanners.

- Skill Requirement: Success depends on the technique and experience of the professional.

- Dry Field: Requires a dry environment (absence of blood and saliva) for effective scanning.

Conclusion

The choice between digital and traditional methods depends on the specific practice and patient needs. Digital impressions offer superior accuracy, comfort, and efficiency, aligning with modern dental trends. However, traditional methods remain viable, particularly where initial costs are a concern or for specific clinical situations.

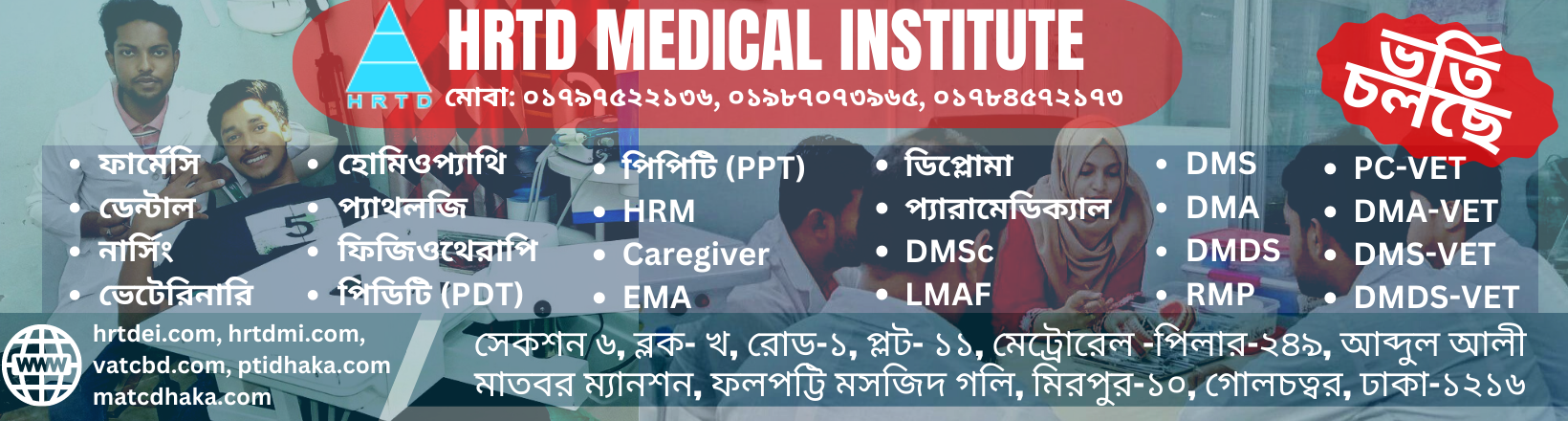

HRTD Medical Institute

HRTD Medical Institute