Flexible Denture Lab. Mobile No. 01941123488, 01797522136. Flexible Denture Lab is Part of the Dental Laboratory where artificial teeth are produced. We produce excellent quality artificial teeth.

What is Flexible Denture

A flexible denture is a type of partial denture made from a pliable, thermoplastic material like nylon that offers greater comfort and a more natural feel than traditional rigid dentures. Unlike rigid dentures, flexible dentures are less prone to breakage, blend better with natural gum tissue, and use transparent, gum-colored clasps instead of visible metal ones. They are an excellent option for patients with partial tooth loss, gum sensitivity, or metal allergies, providing a discreet, durable, and comfortable alternative for replacing missing teeth.

Key Features & Benefits

- Material: Made from soft, thin, thermoplastic materials like nylon, which are BPA-free.

- Comfort: The pliable material adapts to the natural contours of the gums and teeth, offering a more comfortable and natural-feeling fit.

- Discreet Appearance: Transparent or gum-colored clasps attach to existing teeth, making them less visible than traditional metal clasps.

- Durability: The flexible material is more resistant to breakage and chipping than rigid acrylic or metal-based dentures.

- Biocompatibility: Free from metal, making them a suitable option for patients with metal allergies.

- Reduced Irritation: Less likely to cause gum irritation due to their soft, adaptable nature.

- Easy to Clean: The non-porous material is less likely to stain or absorb odors.

Who Are Flexible Dentures For?

Flexible dentures are a great option for people with:

- Partial tooth loss (1-6 teeth).

- Sensitive gums or difficulty wearing rigid dentures.

- Allergies to acrylic or metal.

- A desire for a more discreet and natural-looking tooth replacement.

Important Considerations

- Flexible dentures are a removable solution for partial tooth loss, not a replacement for all teeth.

- While durable, they still require proper care and regular dental check-ups to maintain their condition.

- The material is not chemically bonded to the teeth, and repairs can be difficult or impossible, according to this YouTube video.

Functions of Flexible Denture Lab

A flexible denture lab functions to design and manufacture custom flexible dentures by transforming a dentist’s or technician’s impression or digital scan into a fabricated, high-quality product. Key functions include fabricating frameworks, processing the denture using flexible materials, ensuring aesthetic appeal through translucent materials, and performing a final quality check to guarantee a precise fit, comfort, and durability for the patient.

Key Functions of a Flexible Denture Lab

- Receiving and Analyzing Impressions/Scans: The lab receives patient-specific impressions or digital scans, which are then analyzed to ensure optimal design for the patient’s unique oral anatomy.

- Designing the Denture Framework: Technicians design the internal framework of the denture, focusing on stability and comfort, with flexible materials eliminating the need for metal clasps.

- Processing the Denture: The lab uses specialized materials like Valplast or other thermoplastic nylons to process the denture. This involves heat injection or other methods to create the thin, flexible, and durable product.

- Finishing and Polishing: Once the denture is fabricated, the surfaces are smoothed, polished, and finished to create a lifelike color and appearance that blends with the natural gum tissue.

- Quality Control:The lab performs a final quality check to ensure the denture meets high standards for fit, stability, comfort, and overall patient satisfaction before delivery to the patient.

- Repairs and Add-ons:Some labs also offer services for repairing or adjusting existing flexible dentures, such as adding teeth or performing relines to accommodate changes in the patient’s oral condition.

Location of Flexible Denture Lab

Location of Flexible Denture Lab. Mobile No. 01941123488, 01797522136. HRTD Limited, Abdul Ali Madbor Mansion, Section-6, Block-Kha, Road-1, Metro Rail Piller No. 249, Mirpur-10 Golchattar, Dhaka-1216.

Price of Flexible Denture in our Flexible Denture Lab

Price depens on numbers of lost teeth, condition of surrounding teeth ( Supporting Teeth) and the conditon of gum.

Some Images of Flexible Denture from our Flexible Denture Lab

Here is an image of a set of flexible dentures, showcasing their lightweight, semi-transparent material and natural gum-colored appearance.

Here is an image showcasing three different views of flexible dentures, highlighting their design, flexibility, and natural appearance.

Classification of Teeth

Teeth are classified based on their type, function, and location in the mouth.

1.Classification Based on Type and Function

Teeth are divided into four main types:

- Incisors (Cutting Teeth)

- Located at the front of the mouth (four on the upper jaw, four on the lower jaw).

- Sharp, thin edges designed for cutting and slicing food.

- Canines (Tearing Teeth)

- Pointed teeth next to the incisors (two on the upper jaw, two on the lower jaw).

- Used for tearing and gripping food.

- Strongest teeth in the mouth.

- Premolars (Grinding Teeth)

- Found behind the canines (four on the upper jaw, four on the lower jaw).

- Have flat surfaces with ridges for crushing and grinding food.

- Molars (Chewing Teeth)

- Located at the back of the mouth (six on the upper jaw, six on the lower jaw, including wisdom teeth).

- Have large, flat surfaces to chew and grind food into smaller pieces for digestion.

2.Classification Based on Development

- Primary (Deciduous) Teeth: Also called baby or milk teeth, there are 20 teeth (10 in each jaw).

- Permanent Teeth: The adult set consists of 32 teeth (16 in each jaw).

3. Classification Based on Location

- Anterior Teeth: Includes incisors and canines (front six teeth in each jaw).

- Posterior Teeth: Includes premolars and molars (back ten teeth in each jaw).

Why Flexible Denture is Popular Nowadays

Flexible dentures have gained popularity due to their comfort, durability, and natural appearance. Unlike traditional acrylic or metal-based dentures, flexible dentures are made from a lightweight, flexible thermoplastic material like nylon or Valplast, making them a preferred choice for many denture wearers.

Flexible dentures are popular because they offer greater comfort due to their soft, adaptive material, a more natural appearance with nearly invisible clasps, and increased durability resistant to breakage compared to traditional rigid dentures. They also provide a solution for patients with metal or acrylic allergies and eliminate the need for messy denture adhesives by providing a snug, secure fit.

Reasons for their popularity:

- Enhanced Comfort:The soft, flexible material conforms to the gums, creating a snug and comfortable fit that reduces irritation, pressure points, and sore spots often associated with traditional dentures.

- Superior Aesthetics:Flexible dentures are made from translucent materials, and they use nearly invisible, gum-colored clasps instead of metal ones, which blends seamlessly with the natural teeth and gums for a more discreet and natural-looking result.

- Increased Durability:The malleable nature of the flexible material makes these dentures highly resistant to cracking or breaking, unlike rigid traditional dentures.

- Hypoallergenic Properties:The biocompatible materials, such as nylon, used in flexible dentures are an excellent alternative for patients who have allergies or sensitivities to the acrylic or metal components of traditional dentures.

- No Need for Adhesives:Due to their snug and secure fit, flexible dentures stay in place effectively without the need for sticky denture adhesives.

- Better for Partial Tooth Loss:They are particularly well-suited for patients missing only a few teeth, making them an excellent choice for partial dentures that blend in with remaining teeth.

Advantages of Flexible Denture

- Increased Comfort

- Made from soft, flexible materials that adapt to the shape of the gums.

- Causes less irritation compared to traditional rigid dentures.

- Better Fit & Stability

- Designed to fit snugly without the need for metal clasps or adhesives.

- Reduced risk of slipping or discomfort while eating and speaking.

- Natural Aesthetic Appearance

- Semi-transparent material blends with natural gum color.

- No visible metal parts, making them more discreet.

- Durable & Fracture-Resistant

- More resistant to breaking compared to traditional acrylic dentures.

- Flexible nature allows them to absorb impact better if dropped.

- Hypoallergenic & Biocompatible

- Ideal for individuals allergic to acrylic or metal-based dentures.

- Less likely to cause gum irritation or inflammation.

- Lightweight & Easy to Adapt To

- Less bulky than traditional dentures, making them easier to wear.

- Patients adjust to them more quickly.

Who Should Consider Flexible Dentures?

- Individuals with gum sensitivity or metal allergies.

- Patients seeking a more comfortable alternative to rigid dentures.

- Those looking for aesthetic, lightweight, and durable partial dentures.

Classification of Artificial Teeth or Denture

There are two types of Dentures. Fixed Denture and Removable Denture. Crowns and Bridges are Fixed Dentures and Another Denture is Fixed Denture.

Dentures are classified based on their coverage, material, retention, and function. Here’s a detailed classification:

(A) Complete Dentures (Full Dentures)

- Used when all teeth are missing in either the upper or lower jaw.

- Made of acrylic, porcelain, or flexible material.

- Can be conventional (after gum healing) or immediate (placed right after tooth extraction).

(B) Partial Dentures

- Used when some natural teeth remain in the mouth.

- Attached using metal clasps, precision attachments, or flexible base.

(C) Flexible Dentures (Nylon-Based, e.g., Valplast, TCS, Flexite)

- Made from thermoplastic material.

- Comfortable, lightweight, and fracture-resistant.

- Ideal for patients allergic to acrylic or metal.

(D) Conventional Dentures

- Traditional removable dentures supported by the gums.

- Fabricated after complete gum healing (4-6 weeks post-extraction).

(E) Immediate Dentures

- Placed immediately after tooth extraction.

- Acts as a temporary solution until permanent dentures are ready.

(F) Overdentures

- Fits over remaining teeth or dental implants for better retention.

- Provides more stability compared to conventional dentures.

(G) Implant-Supported Dentures

- Attached to dental implants for enhanced support.

- Improves chewing efficiency and speech clarity.

- Can be removable or fixed.

Process of Receiving and Analyzing Impressions for Flexible Denture

Receiving and analyzing impressions for flexible dentures involves creating a precise 3D model of the mouth, either conventionally with impression materials or digitally with scanners, to design the denture’s framework and teeth. The dentist reviews these impressions, often using custom trays, to capture the unique contours and bite of the patient’s mouth before sending them to a dental lab. The lab then uses these models to fabricate a wax-up, which is tried in the patient’s mouth for adjustments to fit, bite, and aesthetics, leading to the final flexible denture.

Impression Taking

- 1. Preliminary Impressions:A dentist or lab technician may start with preliminary impressions using stock trays to create an initial model or digital scan.

- 2. Custom Trays:For more precise impressions, custom trays are made on the preliminary models to ensure the impression material accurately captures the shape of the mouth.

- 3. Final Impression:High-quality impression materials (like silicone) are used in the custom trays to record the detailed anatomy of the dental arches and surrounding tissues.

- 4. Digital Impressions:Alternatively, a digital scanner can capture thousands of images of the teeth and gums, which are then used to create a 3D digital model.

Impression Analysis & Preparation

- 1. Quality Check:Before sending to the lab, the dentist inspects the impression for any distortions, air bubbles, or areas where detail was missed.

- 2. Digital Transfer:If digital impressions are taken, the 3D data files are electronically sent to the lab.

- 3. Master Model:The impression material is used to create a precise master model (or cast) of the patient’s mouth.

Lab Processing and Analysis

- Wax-Up: Technicians use the master model to construct a wax replica of the final denture, including the framework and teeth.

- Bite and Fit Analysis: This wax-up is sent back to the dentist for a crucial trial fitting. The dentist checks for proper fit of the denture base, the color, shape, and arrangement of the teeth, and the bite (occlusion).

- Adjustments: Any necessary adjustments are noted for the lab.

Finalization

- 1. Denture Fabrication:Based on the adjusted wax-up, the lab fabricates the permanent flexible denture, a process which may include flasking and processing acrylic materials.

- 2. Final Polish and Try-In:The completed denture is then sent back to the dentist for a final try-in and any last adjustments to ensure comfort and a perfect bite.

Designing Process for a Denture Framework

The designing process for a denture framework involves several systematic steps, whether using manual methods or CAD/CAM software. Key components of this process include identifying rest seats and guide planes on abutment teeth, outlining the meshwork for the denture base, designing direct and indirect retainers (clasps) for retention, and establishing a major connector for support and structure. The final design ensures clear communication with the lab technician and incorporates all necessary elements to support the denture and provide patient comfort.

Systematic Design Steps

- 1. Outline the Rests:Place rests on the abutment teeth adjacent to the edentulous (toothless) areas to provide support and prevent the framework from sinking into the gum tissue.

- 2. Design Minor Connectors and Proximal Plates:These components connect the rests to the major connector and framework, and they ensure proper placement and stability.

- 3. Outline the Retentive Meshwork:Create a mesh in the saddle areas where the missing teeth were, considering the support provided by the underlying tissue.

- 4. Select the Major Connector:Determine the type and placement of the major connector, which forms the main structural link of the framework.

- 5. Outline Direct Retainers (Clasps):Design the clasps that will encircle and retain the abutment teeth, ensuring they provide adequate retention without damaging the tooth.

- 6. Outline Indirect Retainers:For specific denture classes (1, 2, 4), design indirect retainers, which are positioned away from the main edentulous area to prevent the denture from tilting or moving.

Digital Design Process (CAD/CAM)

- 1. Data Acquisition:Capture patient anatomy and spatial relationships using an intraoral scanner to create virtual 3D models.

- 2. Computer-Aided Design (CAD):

- Upload scan data into design software.

- Use tools to create the framework by duplicating models and adding offsets for guide planes and clasps.

- Utilize tools to block out undercuts and trim areas, ensuring a proper fit for the framework.

- Add and adjust the thickness of various components using dedicated tools within the software.

- 3. Computer-Aided Manufacturing (CAM):The digital design is sent to a manufacturing unit to create a physical or try-in framework.

Purpose of the Framework

- Support: The rests and major connector provide support for the denture.

- Retention: Direct retainers (clasps) hold the denture in place.

- Stability: Reciprocating elements of the clasps counteract the forces placed on the teeth by the clasps.

- Comfort: The framework’s design is crucial for patient comfort and proper function.

Processing the Flexible Denture

Processing a flexible denture involves creating a duplicate of a master dental model, investing the duplicate model in a flask, removing the wax pattern to create a mold, injecting the thermoplastic resin material into the flask, and then deflasking, finishing, and polishing the final denture. The injection process uses a specialized machine and a cartridge containing the flexible resin material. After the injection, the excess material is removed, the denture is trimmed, and the surface is polished to a smooth finish.

Fabrication Steps

- 1. Impression and Model: A dental impression of the patient’s mouth is taken to create an accurate model of the teeth and gums.

- 2. Wax-Up and Try-In: A wax replica of the denture is made on the model. This wax-up is then tried in the patient’s mouth to check the fit, bite, and appearance of the teeth.

- 3. Flask Preparation: The master model is duplicated, and the wax pattern is invested and placed in a special flask.

- 4. Deflasking: After the wax is removed, the flask is prepared for the resin injection.

- 5. Resin Injection: The flexible thermoplastic resin material is heated and injected into the mold within the flask.

- 6. Cooling: The injected flask is allowed to cool under pressure to ensure proper solidification of the material.

- 7. Deflasking and Retrieval: The flask is opened to retrieve the finished denture, with the sprues (the channels for the injected material) still attached.

- 8. Finishing and Polishing: The sprues are cut, and the excess material is removed. The denture is then smoothed and polished using various burs, brushes, and polishing compounds to achieve a high-luster finish.

Key Processes

- Investment: Placing the wax model into a flask filled with plaster to create a mold for the resin.

- Deflasking: Opening the flask to remove the wax and expose the mold cavity.

- Injection: Using a machine to inject heated thermoplastic resin into the mold under pressure.

- Finishing and Polishing: Trimming the excess material and smoothing the surface of the denture using rotary tools.

Row Materials for Flexible Denture in our Flexible Denture Lab

Raw materials for flexible dentures are primarily flexible thermoplastic polymers, with Nylon (Polyamide) being the most common, often found in brands like Valplast. Other materials include specialized thermoplastic resins like Duraflex, TCS, and Thermoflex, as well as Acetal Resin for slightly more rigidity but still offering flexibility. These materials are chosen for their lightweight feel, comfort, hypoallergenic properties, and ability to adapt to the mouth’s contours, providing a discreet and natural-feeling fit.

Types of materials used in our flexible denture lab

- Nylon-Based Materials (Polyamide)

- Description: A popular choice for flexible partial dentures, these are made from nylon thermoplastic resins that are durable, lightweight, and comfortable.

- Examples: Valplast is a well-known brand that uses this material.

- Benefits: They are hypoallergenic, making them suitable for patients with allergies to acrylics or metals.

- Other Thermoplastic Resins

- Description: Various other thermoplastic materials are used to provide a combination of flexibility, strength, and biocompatibility.

- Examples: Duraflex, TCS (Thermo-Plasticized Resin), and Thermoflex are examples of these high-quality materials.

- Benefits: These materials are designed for long-term use, resisting staining and providing a secure, comfortable fit.

- Acetal Resin

- Description: A thermoplastic material that is somewhat more rigid than nylon but still offers a good degree of flexibility and excellent strength and wear resistance.

- Benefits: Offers greater durability compared to softer nylons, making it a strong and resistant option.

Lasting of Flexible Denture from our Flexible Denture Lab

Flexible dentures typically last 5 to 8 years, though this can vary based on care and maintenance. Proper oral hygiene, regular professional check-ups, and storing them in water or denture solution when not worn can extend their lifespan. Signs that a replacement is needed include visible wear and tear, a poor fit, or structural damage.

Factors Affecting Lifespan

- Care and Maintenance:Daily cleaning with a soft-bristled brush and denture cleaner, along with rinsing after meals, helps prevent buildup and maintains the denture’s integrity.

- Material Degradation:Over time, the material can become stained, cracked, or chipped.

- Oral Health:The condition of your gums and remaining teeth also influences the denture’s longevity.

- Accidental Damage:Dropping the dentures can lead to structural damage that necessitates replacement.

When to Replace Your Flexible Dentures

- Loose Fit: If the denture feels loose or uncomfortable, it may indicate a change in its shape.

- Visible Wear: Look for cracks, chips, or significant staining on the nylon material.

- Structural Issues: Damage from dropping or excessive wear can compromise the denture.

- Gums and Oral Health: A loose denture can irritate the gums, leading to potential oral health problems.

Tips for Extended Wear

- Clean Daily: Brush your dentures with a soft-bristled brush and a mild denture cleaner.

- Rinse After Meals: Rinse your dentures with water to remove food particles.

- Keep Them Hydrated: When not wearing them, store your dentures in water or a denture solution to prevent drying out.

- Regular Dental Check-ups: See your dentist for regular check-ups to ensure your dentures are in optimal condition.

Machinary for Flexible Denture Lab

Machinery for flexible dentures is generally called a dental injection system or denture injection machine, often associated with materials like Valplast. These machines work by heating flexible resin cartridges and injecting the molten material into a flask containing the denture framework. They can range from manual benchtop models to fully automatic industrial systems, depending on the lab’s production needs.

How the machinery works in Flexible Denture Lab

- Heating: The flexible resin cartridge is placed in the machine’s heating tube to reach a specific, preset temperature.

- Injection: Once the resin is heated to the correct temperature, the machine presses the molten material into the dental flask where the denture framework is prepared.

- Curing: The resin then cures and solidifies, forming the flexible denture.

Types of machinery that are used in Flexible Denture Lab

- Manual Systems: These machines require more user involvement, such as manually pressing the resin into the flask.

- Semi-Automatic Machines: Some systems automate the injection process after the heating phase.

- Benchtop and Industrial Machines: The size and power of these machines vary depending on the production load of the dental laboratory.

Key features:

- Temperature Control: Many machines maintain a constant temperature for the resin, preventing failures caused by temperature drops.

- Ease of Operation: Newer models focus on simple, user-friendly operation.

- Durability and Longevity: Look for machines with a long lifespan and low maintenance.

Finishing and Polishing in our Flexible Denture Lab

Finishing and polishing a flexible denture involves using a combination of burs, polishing wheels, and specialized compounds in a multi-stage process. The goal is to smooth the surface and achieve a high-gloss, smooth finish. Key steps include removing excess material, applying polishing compounds, and buffing with various wheels to create the desired luster, all while using light, controlled pressure to prevent warping or distortion of the flexible material.

1. Finishing (Smoothing) in our Flexible Denture Lab

- Initial Smoothing: Begin by using a flexible, felt-type bur or a fine pumice with a rag wheel or brush wheel at a slow to medium speed to remove any remaining imperfections or scratches left from the manufacturing process.

- Contouring: Lightly shape the denture using appropriate burs and wheels, but avoid excessive pressure to maintain the denture’s contours and fit.

2. Polishing (Shining) in our Flexible Denture Lab

- Pumicing:Apply a fine pumice or specialized flexible denture polish (like Polaris or Acrylux) to a soft, wet rag wheel or brush wheel.

- Buffing:Move the denture lightly against the rotating wheel, ensuring the surface remains wet to prevent overheating, and keep the denture moving to avoid distortion.

- Multi-Stage Process:A typical process involves stages:

- Pre-Polish: Use a synthetic pumice (Acrylux) and a soft wheel.

- Tripoli/Brown Compound: Apply a tripoli compound with a dry rag buff to achieve a deep shine and stain resistance.

- Finishing/Shining: Use a specialized “shine” compound with a rag buff at slow to high speeds for a final high-gloss finish.

3. Final Cleaning and Inspection in our Flexible Denture Lab

- Cleaning:After polishing, clean the denture in an ultrasonic cleaner to remove any remaining residues.

- Inspection:Visually inspect the denture to ensure it has a uniform and smooth, glossy surface without any debris.

Key Considerations

- Pressure:Always use light, controlled pressure to avoid damaging the flexible material or distorting the denture.

- Speed:Use the appropriate speed for each stage; start slow and increase gradually as needed.

- Specialized Materials:Utilize specialized flexible denture polishing materials and wheels designed specifically for the flexible material.

- Direction:Maintain a consistent movement direction (up and down or right and left) to achieve a smooth, uniform luster.

Who can by Flexible Denture from our Flexible Denture Lab

Anyone missing teeth, especially those with sensitivities, gum problems, metal allergies, or who prefer a lightweight and comfortable alternative to traditional dentures, can benefit from flexible dentures. They are especially well-suited for patients with partial tooth loss who need a more aesthetic and virtually invisible solution than metal-clasped partials. However, a dentist must assess suitability and fit because they are custom-made devices.

Ideal Candidates for Flexible Dentures

- Partial tooth loss:Those with one or more missing teeth who have healthy remaining teeth are excellent candidates.

- Sensitive gums:The flexible material provides comfort for patients with sensitive gums.

- Metal allergies:Flexible dentures are made from nylon-based thermoplastic materials and do not require metal clasps, making them ideal for those allergic to metal.

- Aesthetic concerns:The transparent, natural-looking clasps are less visible than traditional metal ones, offering a more aesthetic and virtually invisible solution.

- Discomfort with traditional dentures:Patients who find traditional dentures rigid or difficult to wear due to issues like sensitive gums or irregularly shaped teeth can benefit from the increased comfort of flexible dentures.

- Dental implant candidates:If you’re not a candidate for dental implants or other fixed restorations, flexible partials offer an affordable, non-invasive alternative.

Who Should See a Dentist First?

- Custom fitting required:Flexible dentures are custom-made to fit snugly. A dental professional, not the lab itself, determines suitability and takes the necessary impressions to ensure a precise fit.

- Comprehensive assessment:A dentist can properly assess your oral health to determine if flexible dentures are the right solution for your specific needs.

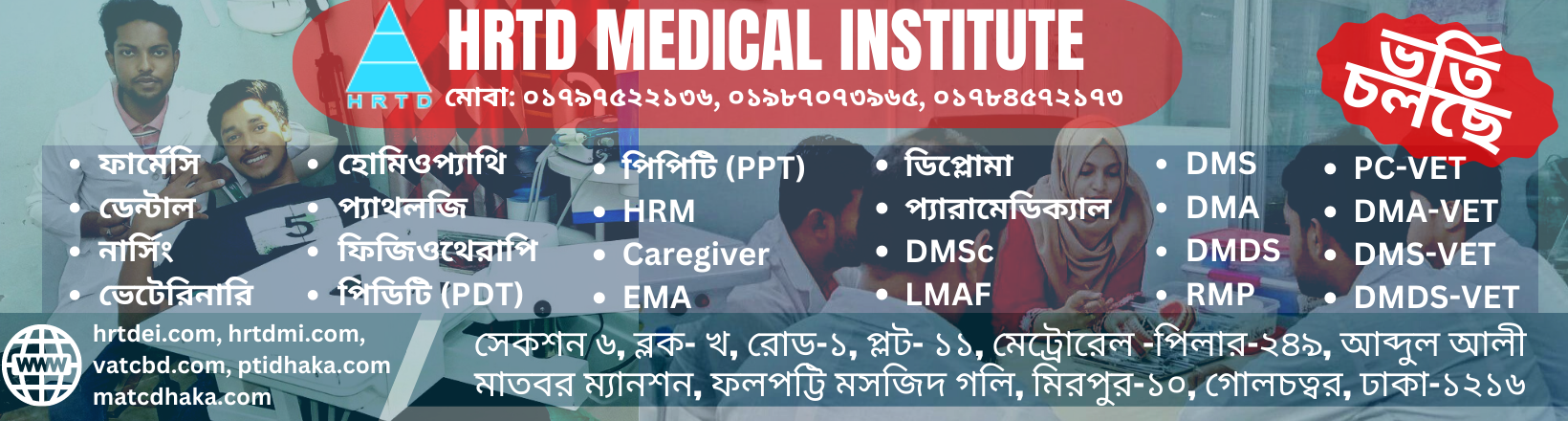

HRTD Medical Institute

HRTD Medical Institute